Constant Variable Transmission (CVT) is a type of automatic transmission that has become increasingly popular in recent years. It is used in many different cars, from hybrid cars to luxury vehicles. Despite its popularity, however, the CVT is not without its issues. As with any vehicle component, the CVT can experience wear and tear over time. If not properly maintained, this can lead to costly repairs, rebuilds, and replacements.

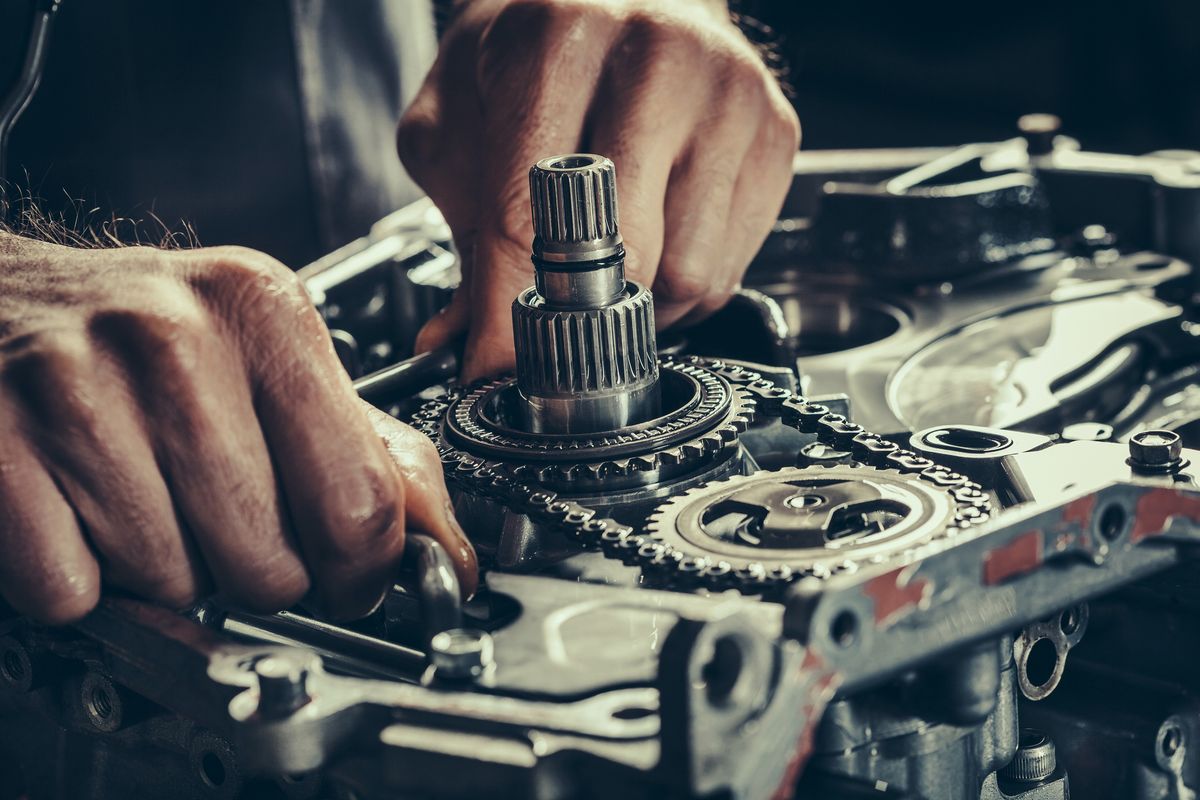

The most common issues associated with CVT transmission repair, rebuild & replacement services are lack of power, or jerking when accelerating. These are all signs that the CVT needs to be repaired or rebuilt. When it comes to repairing a CVT, the first step is to diagnose the problem. This involves checking the fluid level, inspecting the transmission, and running diagnostic tests. If the issue is not too severe, the CVT can be repaired. In some cases, the transmission may need to be rebuilt. This is a more involved process, as it involves replacing internal components and recalibrating them to work together.

Image Source: Google

If the CVT is beyond repair or rebuilding, then it must be replaced. It is important to note that replacing a CVT is a labor-intensive and expensive process. It is recommended to have the CVT replaced only as a last resort, as it is much more costly than a repair or rebuild.

In conclusion, the CVT is an important part of many modern cars, and if it is not properly maintained, it can lead to costly repairs, rebuilds, and replacements. It is important to have any CVT-related issues diagnosed and repaired as soon as possible, as this can help to prevent more serious and expensive problems in the future.