Image Source: Google

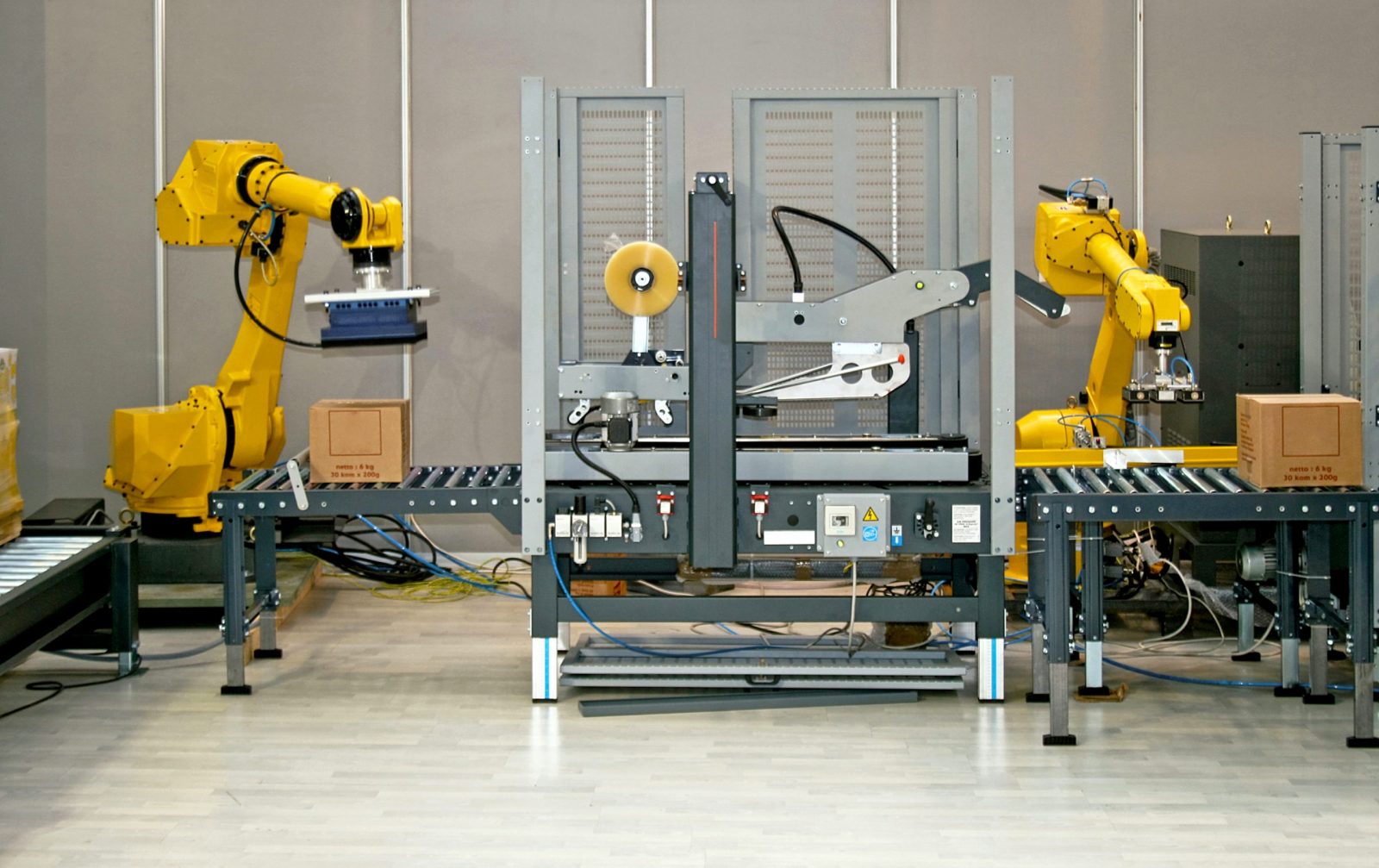

Manufacturing industries are undergoing a significant transformation with the integration of automation technology. Automation technology specialists play a crucial role in this revolution by implementing and maintaining advanced systems that enhance efficiency, productivity, and safety in manufacturing processes. This article explores the key responsibilities and impact of automation technology specialists in revolutionizing the manufacturing sector.

The Role of Automation Technology Specialists

Key Responsibilities

- Designing and implementing automation systems: Automation technology specialists are responsible for designing and implementing automated systems that streamline manufacturing processes. This includes the selection of appropriate technologies, programming, and testing of automation systems. If you want to know more about Automation Technology Specialists then you can explore this website.

- Optimizing system performance: Automation technology specialists continuously monitor and optimize the performance of automation systems to ensure maximum efficiency and productivity. They troubleshoot any issues that may arise and make necessary adjustments to improve system performance.

- Ensuring compliance and safety: Automation technology specialists ensure that automation systems comply with industry regulations and safety standards. They conduct regular inspections and maintenance activities to prevent accidents and enhance workplace safety.

- Training and support: Automation technology specialists provide training to manufacturing staff on how to operate and maintain automation systems effectively. They also offer technical support to address any system-related issues and ensure smooth operations.

Impact on Manufacturing Industry

Enhanced Efficiency and Productivity

- Automation technology specialists play a key role in optimizing manufacturing processes, leading to enhanced efficiency and productivity. By implementing automated systems, they reduce manual intervention, minimize errors, and increase production output.

- Improved Quality and Consistency: Automation systems implemented by specialists ensure consistent quality in manufacturing processes. By eliminating human errors and variability, automation technology specialists help maintain high product quality standards.

- Cost Savings: Automation technology specialists help manufacturing companies save costs by improving operational efficiency and reducing downtime. Automated systems require less manual labor, leading to reduced labor costs and increased overall profitability.

Technological Advancements

- Automation technology specialists drive technological advancements in the manufacturing industry by implementing cutting-edge automation systems. They stay updated on the latest technologies and trends to enhance manufacturing capabilities and stay competitive in the market.

- Integration of Industry 4.0 Technologies: Automation technology specialists play a crucial role in the implementation of Industry 4.0 technologies such as Internet of Things (IoT), artificial intelligence, and data analytics. These technologies enable smart manufacturing processes and data-driven decision-making.

Future Trends and Challenges

Future Trends

- Collaborative Robots (Cobots): Automation technology specialists are increasingly incorporating collaborative robots into manufacturing processes. Cobots work alongside human operators, enhancing productivity and flexibility in manufacturing operations.

- Digital Twin Technology: Automation technology specialists are leveraging digital twin technology to create virtual replicas of physical manufacturing systems. This enables real-time monitoring, simulation, and predictive maintenance of manufacturing processes.

Challenges

- Skills Gap: The rapid advancement of automation technologies poses a challenge in terms of the skills required to operate and maintain these systems. Automation technology specialists need to continuously update their skills to keep pace with technological innovations.

- Cybersecurity Risks: With the increased connectivity of automation systems, cybersecurity threats become a growing concern. Automation technology specialists need to implement robust cybersecurity measures to protect manufacturing systems from cyber attacks.

In conclusion, automation technology specialists play a vital role in revolutionizing the manufacturing industry by implementing advanced automation systems, enhancing efficiency, and driving technological advancements. Their expertise is essential in maximizing productivity, ensuring quality, and staying competitive in a rapidly evolving manufacturing landscape.